|

| Lang Dulay, Manlilikha ng Bayan, Master Dreamweaver |

The Bajaus have their colorful mats, the Yakans their equally hue-filled cloth, and the T'bolis have their T'nalak. I'm not much of a souvenir collector or a memento keeper but I find these crafts fascinating. Most are a bit pricey (I'm such a cheapskate) though I understand that each is painstakingly crafted by hand. For a deeper appreciation of the T'nalak, we got a firsthand look into how much labor of love goes into making this cloth during our trip.

|

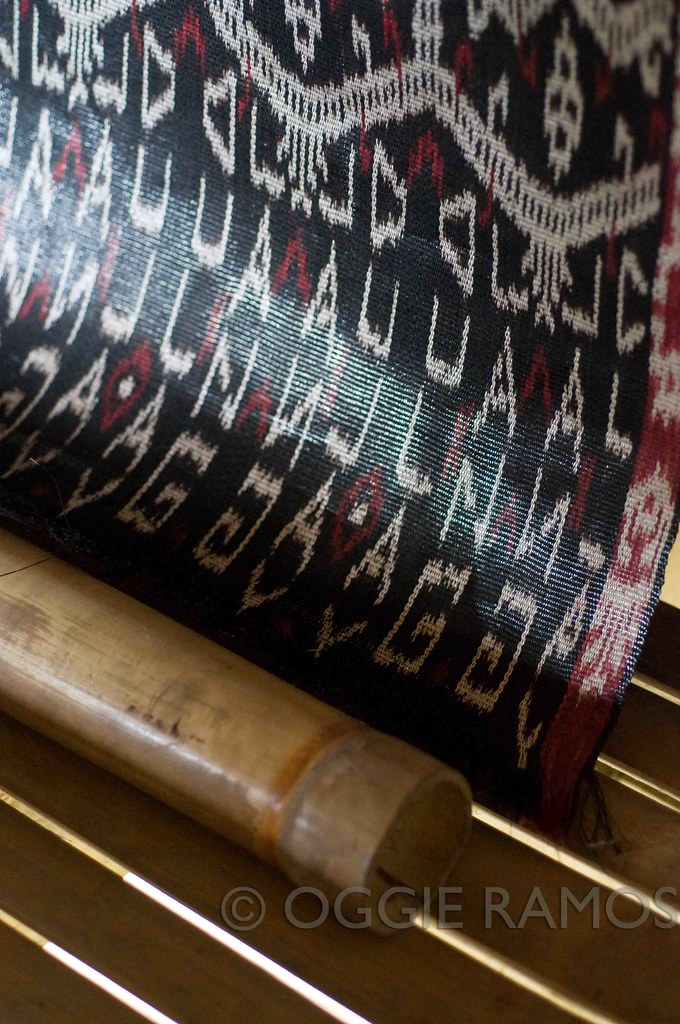

| Finished T'nalak with Lang Dulay's name woven into the pattern |

|

| Lang Dulay oversees the design and weaving |

We went around her gunu bong or longhouse (the quintessential T'boli abode built on stilts) which I believe is also the training venue for her students. One section was devoted to the making of the patterns; another to the weaving manned by her apprentices. Her progeny and descendants, both biological and cultural, mill around the longhouse while we admire her works. What language failed to communicate, her designs were able to bridge. We walked away with newfound respect for this living treasure and optimism that the art of T'nalak weaving is alive and well.

|

| Weaver in a pensive moment |

Weaving 101. Next, we ventured to Bo. Lamangdalag, about an hour away from the poblacion via motorcycle passing through dirt and rough roads, to learn and appreciate how much work goes into the T'nalak. This is a longhouse help built by Lang Dulay and the Cowhed (Cooperative of Women for Health and Education) through the auspices of the International Labor Organization (ILO).

Explaining the process is tedious in itself; the making of the T'nalak more so. The abaca plant is first stripped of its fibers. The fibers are then sifted by hand and dried. After that, these are tied to form threads later wound into balls. Next, the threads are stretched across a bamboo frame where the pattern maker define the design by meticulously putting plastic straws on parts of the thread. The threads are then boiled in vegetable dye with the portions tied with plastic straw left un-colored to produce the pattern. These are then dried. If the design requires more colors, the process of putting straws on parts of the thread, boiling in dye and drying are repeated again and again.

Then the weaving begins with the dyed fibers stretched across a loom with a backstrap to give tension to the weave. Depending on the complexity of the design and length of the cloth, the weaving can take anywhere from three to six months; the cloth for a wedding dress can take up to a year to finish. The fragile nature of the abaca fiber also dictates that weaving be done during the cooler hours of the early morning or evening when the fiber is less brittle. When finished, the cloth may be ironed with a shell to give it a luminescent gloss.

Spinning yarns and weaving beliefs. The making of the T'nalak is fraught with beliefs and practices that give the cloth an even more textured story. Like the weaver is not supposed to walk over and across the outstretched threads so as not to get sick. The cloth shouldn't be washed with soap since it is sacred. When weaving certain designs, the weavers forgo months of intimacy perhaps so as not to disturb the flow of divine inspiration. Hmmm, this last one is one I find most interesting for perhaps, one can put a price on cloth but cloth with patterns spun by tradition and shaped by dreams? That's priceless.

Thank you note: Backpack Photography thanks the ILO staff of Lake Sebu, Cowhed (Cooperative of Women for Health and Education) and Sta. Cruz Mission for allowing us to gain insights on the T'nalak making process and the cooperative of T'nalak weavers. Attribution: National Commission for Culture and the Arts • WikiPilipinas

Coming up in Lagalog: Zipping over five falls in (about) 60 seconds